Formaldehyde is a colorless gas with a strong pungent odor. Soluble in water, alcohol and ether. 35%~40% formaldehyde solution is called formalin. Formaldehyde is an important organic raw material, mainly used in plastic industry, synthetic fiber, leather industry, medicine, dye and wood adhesive production process.

Hazards: Formaldehyde is highly toxic to humans and warm-blooded animals. It can irritate the skin, easily cause dermatitis, and easily produce respiratory irritation, allergies, abnormal lung function, abnormal liver function, and abnormal immune function. If humans drink water contaminated with formaldehyde for a long time, it will cause dizziness, anemia and various neurological diseases. Due to the wide use of formaldehyde in industrial production, complete restriction is unrealistic, and the produced formaldehyde wastewater must be treated.

The national standard “Integrated Wastewater Discharge Standard” (GB8978-1996) stipulates that the formaldehyde content of the secondary discharge standard shall not be higher than 2mg/L. However, formaldehyde can directly react with proteins, DNA, and RNA in microorganisms, resulting in the death of microorganisms or inhibiting their biological activity. After more than 200mg/L, the microbial activity is almost completely inhibited, so high concentrations of formaldehyde are not suitable for biological treatment; and formaldehyde The form of the solution is a true solution, and the coagulation process is also difficult to work.

Domestic and foreign researchers have carried out a lot of research on the treatment technology of formaldehyde wastewater. Formaldehyde wastewater treatment methods mainly include: oxidation method, biological treatment method, stripping method, condensation method, lime method, etc.

1. Oxidation method

Fenton’s reagent oxidation treatment of formaldehyde wastewater is a method widely studied by scholars at home and abroad. The reagent is a strong oxidant composed of H2O2 and Fe2+. It mainly utilizes highly active hydroxyl radicals (·OH) to oxidatively degrade organic matter in wastewater, and achieve complete degradation of organic matter in a short time.

2. Wet oxidation method

Under the condition of no external catalyst, at 180-315℃ and 2-15MPa, the organic and inorganic carbon in the wastewater containing formaldehyde will selectively become CO2 and H2O, without producing nitrogen oxides, sulfur oxides, Hydrogen chloride, fly ash, etc. After adding CuO-ZnO/Al2O3 catalyst, the reaction time is shortened, and the temperature and pressure can also be reduced to 130-250℃ and 1-5MPa. According to relevant studies, the removal rate of formaldehyde and CODCr can reach more than 90%.

3. Photocatalytic oxidation method

Photocatalytic oxidation technology is an emerging environmental protection technology that has been gradually developed since the 1970s. It utilizes the characteristics of the surface energy of semiconductor oxide materials to be activated under light, which can effectively oxidize and decompose organic matter, reduce heavy metal ions, kill bacteria and eliminate peculiar smell, especially the most commonly used TiO2 system. In 1974, Honda et al. first discovered that TiO2 can decompose water into H2 and O2 under light conditions, and the photocatalytic oxidation method was quickly applied to wastewater treatment, especially all kinds of organic substances that are difficult to biodegrade. Studies have shown that photocatalytic oxidation can effectively treat low-concentration formaldehyde wastewater. The removal rate is over 90%.

4. Chlorine dioxide method

Chlorine dioxide (ClO2) is an excellent disinfectant, bleaching agent and high-efficiency oxidant. Its effective chlorine content is as high as 263%, which is 2.6 times the oxidizing ability of chlorine gas. It has no carcinogenicity and teratogenicity at all with its sterilization and disinfection, and is listed as an AI-grade product by the World Health Organization (WHO), ranking first in safe disinfection methods. Yue Qinyan and others studied the effect of time and pH value on the treatment of formaldehyde wastewater. When the concentration of formaldehyde in the wastewater is 8.25 mg/L, the removal rate of formaldehyde can reach up to 80% after 30 min of reaction. Optimal under neutral conditions.

5. Ultrasonic/H2O2 oxidation method

Hydrogen peroxide (H2O2) is a common oxidant that can treat formaldehyde wastewater alone or in combination. Yan Bing et al. have shown through research that the use of this combined method can make the formaldehyde removal rate reach more than 80%, but the reaction rate is not high. The degradation reaction conformed to the first-order kinetic model, and the reaction rate increased with the decrease of the initial concentration. Alkaline conditions are favorable for the progress of the reaction.

6. Biological treatment method

The biological treatment of formaldehyde wastewater mostly adopts the combination of anaerobic hydrolysis acidification and aerobic biological treatment. It is generally believed that formaldehyde wastewater exceeding 200 mg/L has inhibitory and killing effects on various microorganisms and bacterial species. Therefore, formaldehyde wastewater exceeding 200 mg/L or even several thousand mg/L cannot be directly treated by biological treatment. , must be preprocessed. Reduce the formaldehyde concentration to a safe concentration that can be degraded by microorganisms, generally less than 50 mg/L, and then use biological treatment to degrade CODCr.

7. Blow-off method

This method uses the characteristics of formaldehyde to be easily soluble in water, low boiling point and easy to volatilize, and the formaldehyde in the production wastewater is stripped and pretreated with steam, so as to reduce the load of the subsequent treatment process and improve the treatment effect. The production wastewater is stripped and treated, and the volatilized formaldehyde gas can be used as a production raw material after being recovered to form a 37% formaldehyde solution. However, this method is suitable for formaldehyde wastewater with extremely high concentration (above 5000mg/L), and the formaldehyde concentration cannot be reduced to below 200mg/L through treatment. It needs to be combined with other pretreatment methods, and the energy consumption is relatively large. In addition, combined with production equipment, there are often already separation and other processes to recover formaldehyde, which is not economical for repeated processing.

8. Condensation method

The condensation method is also called the urea method. Mainly, the reaction of urea and formaldehyde under acidic conditions can generate methyl urea precipitation. The basic method is: adjust the pH of the formaldehyde wastewater with hydrochloric acid to about 2, and add an appropriate amount of urea in proportion to make the removal rate of formaldehyde reach more than 80%. However, this method, like the stripping method, is suitable for extremely high-concentration formaldehyde wastewater, which cannot meet the needs of subsequent biochemical treatment. This method is mostly laboratory research, and industrial application has yet to be practiced.

9. Lime method

When formaldehyde is heated under alkaline conditions, a resinification reaction can occur. This principle can be used to treat formaldehyde wastewater. The most commonly used catalyst is Ca(OH)2. In the presence of lime, formaldehyde polymerizes to form hexose sugars. Although this method cannot reduce CODCr, the converted sugars do not have any toxic effect on microorganisms and are helpful for the growth of microorganisms. It is very beneficial for subsequent biological treatment. The main method is: use sodium hydroxide to control the formaldehyde wastewater to be alkaline (pH is 11-12), add lime in the ratio of the mass concentration ratio of lime and formaldehyde to 0.1, and control the temperature to be about 70 °C. It shows that the removal rate of formaldehyde concentration can reach more than 99%. There are two main factors for the removal of formaldehyde concentration in this method. Theoretically, the larger the dosage of lime, the higher the temperature, and the faster and more thorough the reaction will be.

Abuot Jiangsu Peier membrane

Jiangsu Peier membrane corp.,Ltd(Stock Code: 836744) was established in 2007 with a registered capital of 48 million Yuan, referred to as “Peier membrane industry”.

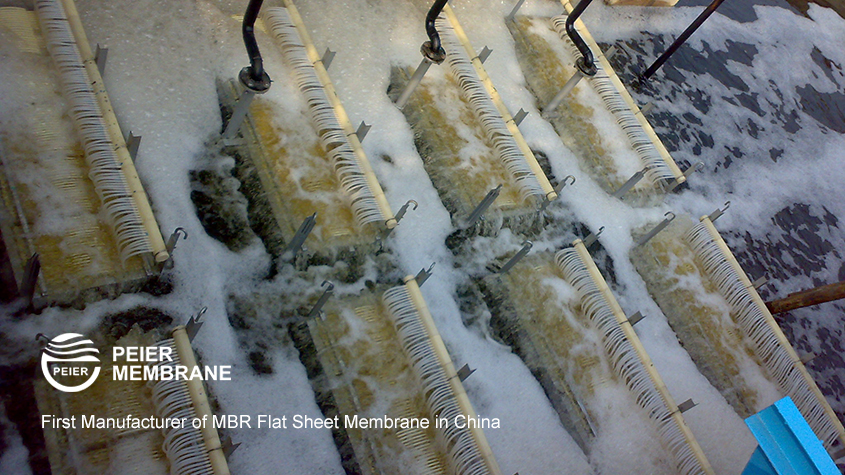

It is a high-tech enterprise focusing on the R&D, production, manufacturing and service of MBR flat sheet membrane products. Its Peier Product category as below:

- Flat Sheet Membrane Element

- Flat Sheet Membrane Element-Single Nozzle

- Flat Sheet Membrane Element-Double Nozzle

- Flat Sheet Membrane Element-3D Soft Support

- Flat Sheet Membrane Element-Renovated Membrane

- Flat Sheet Membrane Module

- Flat Sheet Membrane Module-Module-Single Nozzle

- Flat Sheet Membrane Module-Module-Double Nozzle

- Flat Sheet Membrane Module-2S(Double Deck)

- Flat Sheet Membrane Module-3S(High Flux)

- Flat Sheet Membrane Module-Mini Module

- MBR System

- MBR System-Laboratory Test Equipment

- MBR System-Pilot Equipment

- MBR System-Package System

Peier membrane always adheres to R&D and cooperation with well-known universities at home and abroad, such as Tsinghua University, Sydney University, Nanjing University of technology, Changzhou University and Jiangnan University.

It is the editor in chief of the national industry standard HY/T252-2018 “submerged flat membrane element for water treatment”.

At present, it has 6 invention patents, 46 new utility patents, 1 appearance patent and 4 software works.