The application research of MBR in the field of sewage treatment began in the United States in the 1960s. The early membrane technology mainly used ultrafiltration tubular membranes. Later, in order to save energy, hollow fiber membranes were developed. At present, MBR mainly includes hollow fiber membranes, tubular membranes and flat membranes. Hollow fiber membranes are often used in integrated equipment and general sewage treatment. Tubular membranes are often used in the field of landfill leachate treatment. , Sewage treatment is gradually used in large quantities.

MBR is generally composed of membrane modules and bioreactors. Compared with traditional bioreactors, it has the characteristics of less space, stable operation, and convenient maintenance and management.

The flat film is a piece of board (usually ABS) with a diversion channel on it, a film made of lining cloth and PVDF material on both sides, and a piece of film formed after seamless welding. There are also two types of membranes, also known as flat membranes, one is a flexible membrane and the other is a flexible membrane.

Flat membranes are widely used and have the characteristics of simple operation, convenient maintenance, low energy consumption and strong adaptability. They have been gradually applied in more and more sewage treatment.

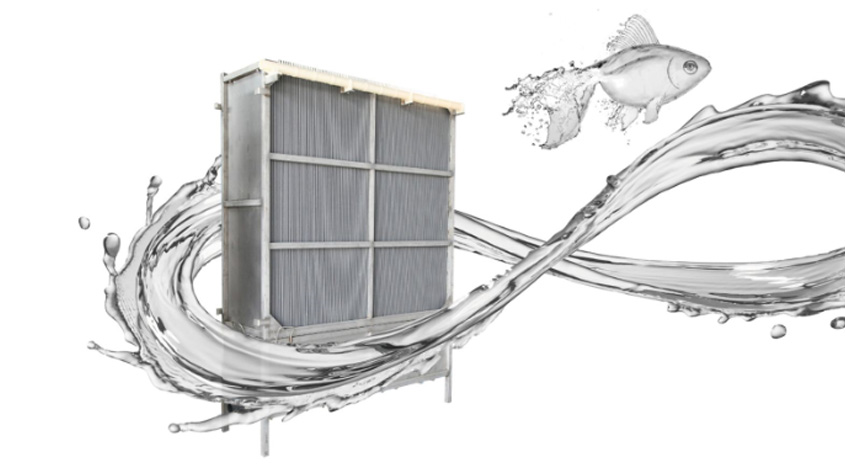

01 MBR Flat Membrane Module

The common one is a shelf welded by 304 stainless steel, and the diaphragms are inserted into it for fixing, and the aeration pipe fittings and water collecting pipe fittings are installed, which is called a membrane module. The current common 10-250 pieces can be integrally formed into components, regardless of the size of a single film.

Theoretically speaking, after the diaphragm is damaged and the water production drops, it can be checked and replaced one by one, thereby saving the replacement cost.

02 Selection of MBR membrane modules

Select the membrane flux according to the water quality, 10-26L/m2h, for example: domestic sewage can choose 18-22L/m2h, electroplating, medicine and other wastewater can choose 12.5-15L/m2h for calculation. Also pay attention to the composition of the treated water entering the membrane pool, whether there is a large amount of oil, calcium and magnesium ions, and organic solvents that can be mixed with the membrane.

03 Installation of MBR flat film

Flat film is divided into dry film and wet film.

Normal situation: Generally, membrane elements and membrane supports are transported to the project site separately. Membrane elements are to be individually sealed and packaged into wooden boxes and brackets to be transported to the site according to the quantity, and can be stored on site.

Special circumstances: It can be assembled and transported to the project site. If the construction site does not have specific installation conditions or the components can be installed immediately after arrival, they can be assembled into components and transported together, which can reduce installation time and improve construction efficiency.

During installation, the components need to be welded to the bottom of the pool, then some water is injected, and the membrane elements are inserted into the modules one by one (here, it is important to remind that the membrane elements are very fragile, and the piece of membrane that is scratched can be thrown away, and the price is relatively expensive.)

04 Cleaning of MBR membrane modules

The operating pressure of the flat membrane is 0-35KPa. Under the action of the self-priming pump (10 minutes is a working cycle, 8 minutes is pumped and 2 minutes is stopped), the mixture is passed through the microporous filter membrane made of polymer material, using Its uniform pore size is used to retain particles, bacteria, etc. in the water, so that they cannot be removed through the filter membrane, and the mud-containing sewage in the biochemical reaction tank is filtered to realize the separation of mud and water.

Therefore, the flat membrane plays the role of filtration:

1. The membrane retains the microorganisms in the reaction tank, which greatly increases the concentration of activated sludge in the tank (the common concentration is about 6000-12000mg/L), so that the biochemical reaction of degrading sewage proceeds more quickly and thoroughly;

2. Due to the high filtration precision of the membrane, the effluent is guaranteed to be clear and transparent, and high-quality water is obtained. Those that can pass through the pore size that cannot be filtered will form fouling near the membrane pores, that is, the membrane is blocked, the water produced is insufficient, and the flux cannot be reached.

The cleaning of membrane modules is mainly divided into: online cleaning and offline cleaning.

The cleaning cycle depends on the pollution of the membrane. For better water quality such as domestic sewage, it may be cleaned once every 3 or 4 months, and for poor water quality such as landfill leachate, it needs to be cleaned every 15 days or 20 days. Press to judge.

The common cleaning is to wash with alkali first and then pickle according to the situation. Alkaline washing is mainly a mixed aqueous solution of sodium hypochlorite and sodium hydroxide. Pickling commonly used oxalic acid or citric acid.

Simple operation for cleaning:

When the membrane is slightly polluted, the online cleaning method can be used, which is simple in operation, low in cost and obvious in effect; generally, alkali cleaning is performed first, followed by acid cleaning, and gravity flow or metering pump can be used for dosing.

Alkaline washing: prepare a mixed aqueous solution of 2000-5000mg/L sodium hypochlorite and 1000mg/L sodium hydroxide, use a high-level cleaning water tank to hydrostatically fill the suction pipe to the membrane element, the dosage of the liquid is 3-5L/piece, soak 5 hours or more.

Pickling: prepare 1000mg/L oxalic acid (or citric acid) solution, clean online, the same amount of water as above, soak for 3-5 hours.

Note: The above drugs are calculated according to the purity of 100%. When the selected drug contains impurities, the corresponding dose is calculated according to the corresponding purity. The liquid medicine is injected into the diaphragm through the dosing port reserved on the membrane suction pipeline by the gravity self-flow method of the liquid medicine to clean the diaphragm.

Offline cleaning is also known as cleaning under maintenance. Generally, off-line cleaning is performed within one year or when the membrane flux cannot be restored by online cleaning. Set up an off-line cleaning tank or cleaning in the membrane tank, that is, the whole tank is immersed with medicine as a whole, and the flux is restored by aeration flushing.

Abuot Jiangsu Peier membrane

Jiangsu Peier membrane corp.,Ltd(Stock Code: 836744) was established in 2007 with a registered capital of 48 million Yuan, referred to as “Peier membrane industry”.

It is a high-tech enterprise focusing on the R&D, production, manufacturing and service of MBR flat sheet membrane products. Its Peier Product category as below:

- Flat Sheet Membrane Element

- Flat Sheet Membrane Element-Single Nozzle

- Flat Sheet Membrane Element-Double Nozzle

- Flat Sheet Membrane Element-3D Soft Support

- Flat Sheet Membrane Element-Renovated Membrane

- Flat Sheet Membrane Module

- Flat Sheet Membrane Module-Module-Single Nozzle

- Flat Sheet Membrane Module-Module-Double Nozzle

- Flat Sheet Membrane Module-2S(Double Deck)

- Flat Sheet Membrane Module-3S(High Flux)

- Flat Sheet Membrane Module-Mini Module

- MBR System

- MBR System-Laboratory Test Equipment

- MBR System-Pilot Equipment

- MBR System-Package System

Peier membrane always adheres to R&D and cooperation with well-known universities at home and abroad, such as Tsinghua University, Sydney University, Nanjing University of technology, Changzhou University and Jiangnan University.

It is the editor in chief of the national industry standard HY/T252-2018 “submerged flat membrane element for water treatment”.

At present, it has 6 invention patents, 46 new utility patents, 1 appearance patent and 4 software works.