First, the definition of sewage load

1. Load:

Generally speaking, there are two types of load: sludge load and volume load, which respectively refer to the amount of COD removed (kg) from a certain amount of sludge (kg) within a certain period of time (day), and a certain reaction volume within a certain period of time (day). (cubic meters) Amount of COD removed (kg).

2. Shock load:

During the operation of sewage treatment, the amount of sludge is generally maintained at a certain level, and the volume of the reactor (aeration tank, anaerobic reactor, etc.) will of course not change. However, if the quality of the influent water changes greatly (COD soars or drops significantly), the sludge load and volumetric load will change greatly, which will affect the sludge microorganisms, which is the so-called shock load.

3. In some treatment processes (especially some with particularly large return flow or complete mixing type), due to some hydraulic or other aspects of design, the process is relatively resistant to shock loads. Even if there is an increase in the load, it will not collapse immediately and can recover relatively quickly. That is, the ability to resist shock loads is strong.

Second, the understanding and calculation of the load of the sewage system

1. Operating load rate = daily actual water intake/daily designed processing capacity. Generally, the operating load rate is required to be no less than 60%. In 2010, although the national average operating load rate of urban sewage treatment plants was close to 80%, and some even exceeded 100%, the state stipulated that the operating load rate should not exceed 120% of the designed treatment capacity. .

2. BOD load = (influent BOD × influent volume) / (V pool capacity × MLSS) this is MLSS load BOD load = (influent BOD × influent volume) / (V pool capacity × MLVSS) This is MLVSS load.

3. Sludge volume: the volume of sludge with a concentration of 1% can be considered to be the same as that of water, and the volume of sludge with a concentration of 5% can be considered to be the same as that of water. Sludge refers to 10 kg of solid matter per ton of sludge with a concentration of 5%, which means that there are 50 kg of solid matter per ton of sludge, so the sludge moisture content is 99%, and it is reduced to 95%, which is 5 tons of sewage. Sludge becomes one ton of sludge. This means that the volume of sludge will be reduced by 5 times.

How much will the volume of activated sludge with a moisture content of 99% be reduced when it is concentrated to a moisture content of 97%?

Dry matter is conserved, and the density is approximately 1V99×ρ×(1-99%)=V97×ρ×(1-97%) V97/V99=1/3, so the volume is reduced from 3 to 1, about 66%

4. Sedimentation tank and outlet weir load: The surface load of the sedimentation tank and the outlet weir load are hydraulic loads, which have little to do with biological treatment. All are design parameters. The surface load of the sedimentation tank: When a particle settles through a distance exactly equal to the depth of the tank within the theoretical residence time, its sedimentation rate is called the overflow rate or the surface load rate. The dimension is the number of cubic meters per square meter per unit time, that is, the number of meters per unit time. The efficiency of a sedimentation tank is usually based on the surface load rate, expressed in cubic meters of water flow per square meter of water surface area per day. It is the water volume divided by the effluent weir load of the sedimentation tank area: that is, the effluent flow of a certain length of the weir, that is, the flow divided by the length of the weir.

5. The organic load rate is the ratio of the amount of influent organic matter to the amount of sludge in the reactor.

6. Sludge age refers to the average residence time of microorganisms in the reaction system from their generation to the discharge system, that is, the time required for all the microorganisms in the reaction system to be renewed once. Under stable conditions, that is, the total amount of activated sludge working in the aeration tank and the amount of excess sludge discharged every day are longer than the usual sludge age, the bacterial species diversity is more, and the organic load rate can be relatively improved. But it is not absolute.

From a kinetic point of view, under the premise of keeping the biomass concentration MLVSS in the pool, the influent flow rate, and the same (please pay attention to this premise), an increase in the load (increase the COD concentration in the influent) will lead to an increase in the COD concentration in the effluent, and the pollution will increase. The mud grows faster, and in order to maintain MLVSS, the mud is discharged faster, that is, the mud age becomes smaller. vice versa. But this kinetic reaction has a range.

The response based on this is as follows: u=1/SRT=umax*Se/(Se+Ks)——MonodNs=Q*So/(V*X)——–Organic load increases and countermeasures for the increase of influent load in practical projects and building As mentioned by engineerxia, “the organic load rate can be relatively increased. But it is not absolute.” It can be analyzed in this way: for an existing system, adjusting the residence time and changing the structures are mostly unworkable, and the only thing that can be changed is the sludge. Concentration and sludge volume control. In order to ensure the water quality of the effluent (when the Se remains unchanged, the growth rate of unit microorganisms and the absorption of pollutants is constant), it is necessary to increase the MLVSS to achieve increased load absorption. The actual operation is to reduce the amount of sludge discharged, and then increase the MLVSS. , After the effluent reaches the standard, gradually increase the amount of sludge discharge. The final balance is that the MLVSS is larger than that before the load is increased, and the absolute amount of sludge discharge also increases. Under the final stable condition, Ns did not change, and SRT did not change, but a new balance point was formed!

7. Surface load The flow through the unit surface area of the sedimentation tank per unit time is called the surface load or overflow rate, which is usually expressed by q, q=Q/A (that is, the ratio of flow to surface area)

8. The number of kilograms of five-day biochemical oxygen demand per kilogram of activated sludge per unit time in the sludge load aeration tank. The unit of measurement is usually expressed in kg/(kg·d).

Sludge load (Ns) refers to the amount of pollutants removed per unit mass of activated sludge per unit time. The meaning of sludge load in terms of microbial metabolism is the F/M ratio, in units of kgCOD (BOD)/(kg sludge.d)

In different stages of sludge growth, the sludge load is different, and the purification effect is also different. Therefore, the sludge load is one of the main parameters for the design and operation of the activated sludge process. Generally speaking, when the sludge load is in the range of 0.3-0.5kg/(kg.d), the removal rate of BOD5 can reach more than 90%, the SVI is 80-150, and the adsorption performance and sedimentation performance of the sludge are good.

Calculation method of sludge load:

Ns=F/M=QS/(VX)

where:

Ns – sludge load, kgCOD (BOD)/(kg sludge.d);

Q – water intake per day, m3/d;

S ——COD (BOD) concentration, mg/L;

V ——effective volume of aeration tank, m3;

X — sludge concentration, mg/L.

9. The treatment load of full-load sewage generally refers to the amount of sewage treated or the total amount of pollutants under the premise that the sewage treatment system can stably meet the standard for incoming sewage. For example, the design of a sewage plant is 2000m3/d, and the influent COD is 1000mg/L, but the actual incoming water is 1000m3, and the incoming water COD is more than 2000. If the treated effluent is stable and meets the standard, it can be said that the system has reached full capacity. Of course, this full load is relative. The designer’s design instructions will mention the organic load of microorganisms in the sewage treatment unit and the concentration of microorganisms in the pool. It has improved its processing power and can also be fully overloaded. The general design indicators are the parameters with relatively stable operation, and it is okay to be higher or lower. In the process of increasing the load, the biomass and unit removal capacity are gradually increased, and the amount of treated sewage is gradually increased. This process is the process of debugging. The indicator of this debugging is that the quality of the effluent is qualified and the effluent is stable, and the sewage load can be gradually increased until it runs at full capacity.

Abuot Jiangsu Peier membrane

Jiangsu Peier membrane corp.,Ltd(Stock Code: 836744) was established in 2007 with a registered capital of 48 million Yuan, referred to as “Peier membrane industry”.

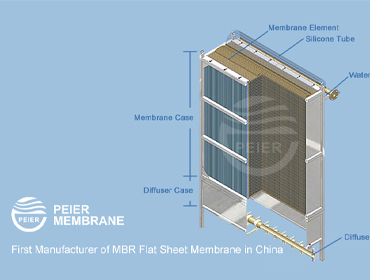

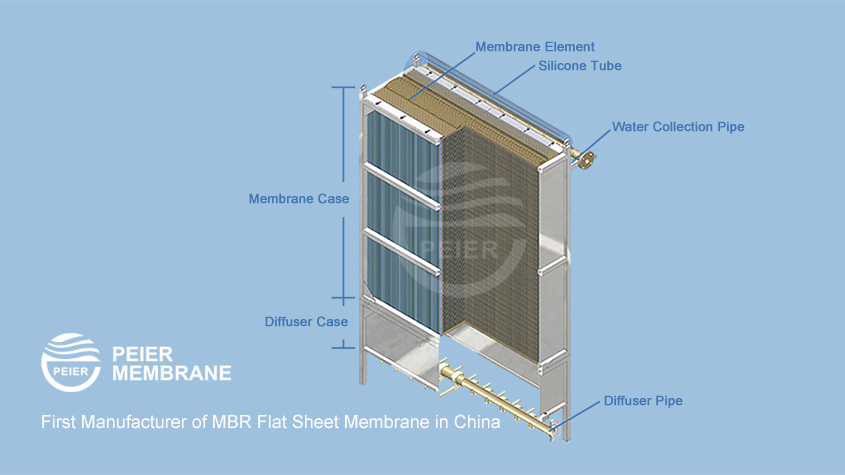

It is a high-tech enterprise focusing on the R&D, production, manufacturing and service of MBR flat sheet membrane products. Its Peier Product category as below:

- Flat Sheet Membrane Element

- Flat Sheet Membrane Element-Single Nozzle

- Flat Sheet Membrane Element-Double Nozzle

- Flat Sheet Membrane Element-3D Soft Support

- Flat Sheet Membrane Element-Renovated Membrane

- Flat Sheet Membrane Module

- Flat Sheet Membrane Module-Module-Single Nozzle

- Flat Sheet Membrane Module-Module-Double Nozzle

- Flat Sheet Membrane Module-2S(Double Deck)

- Flat Sheet Membrane Module-3S(High Flux)

- Flat Sheet Membrane Module-Mini Module

- MBR System

- MBR System-Laboratory Test Equipment

- MBR System-Pilot Equipment

- MBR System-Package System

Peier membrane always adheres to R&D and cooperation with well-known universities at home and abroad, such as Tsinghua University, Sydney University, Nanjing University of technology, Changzhou University and Jiangnan University.

It is the editor in chief of the national industry standard HY/T252-2018 “submerged flat membrane element for water treatment”.

At present, it has 6 invention patents, 46 new utility patents, 1 appearance patent and 4 software works.