Water purification is a critical process that ensures the availability of clean and safe drinking water for human consumption. Over the years, advancements in filtration technologies have revolutionized water purification, with submerged flat sheet membrane modules emerging as a game-changer. This article aims to explore how submerged flat sheet membrane modules have revolutionized water purification, highlighting their benefits, applications, and contributions to achieving sustainable and high-quality water treatment.

1. The Need for Effective Water Purification:

Access to clean and safe drinking water is essential for human health and well-being. However, water sources are increasingly contaminated with pollutants, including bacteria, viruses, suspended solids, and organic compounds. Traditional water treatment methods, such as sand filtration and chemical disinfection, have limitations in removing these contaminants effectively. Hence, the development of advanced filtration technologies, like submerged flat sheet membrane modules, has become crucial.

2. Introduction to Submerged Flat Sheet Membrane Modules:

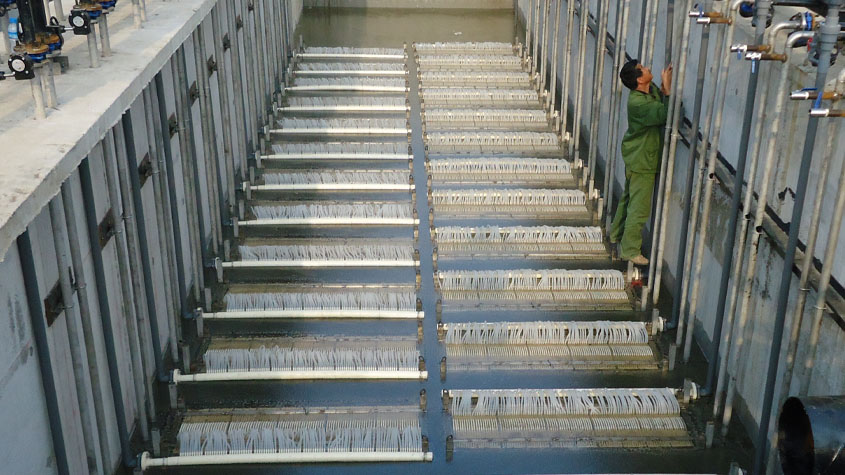

Submerged flat sheet membrane modules are innovative filtration systems that utilize a highly efficient membrane technology to purify water. These modules consist of flat sheet membranes with microscopic pores, which act as a physical barrier to separate impurities from water. The submerged configuration allows for continuous filtration, ensuring consistent and high-quality treated water.

3. Benefits of Submerged Flat Sheet Membrane Modules:

a) Superior Filtration Performance: Submerged flat sheet membrane modules offer exceptional filtration performance, removing suspended solids, bacteria, viruses, and even certain organic compounds. The small pore size of the membranes ensures a high level of purification, resulting in clean and safe drinking water.

b) Enhanced Water Recovery: Submerged flat sheet membrane modules enable a significant portion of treated water to be recovered, reducing water wastage and improving overall water use efficiency.

c) Consistent and Reliable Operation: The submerged configuration of the modules ensures continuous filtration, minimizing downtime and ensuring a consistent supply of purified water.

d) Space-Efficient Design: Submerged flat sheet membrane modules have a compact design, making them suitable for installation in various water treatment facilities, including small-scale and decentralized systems.

4. Applications of Submerged Flat Sheet Membrane Modules in Water Purification:

a) Municipal Water Treatment: Submerged flat sheet membrane modules are widely used in municipal water treatment plants to purify drinking water. They effectively remove suspended solids, bacteria, and other contaminants, ensuring the delivery of clean and safe water to communities.

b) Industrial Water Treatment: Industries that require high-quality water for their processes, such as pharmaceuticals, food and beverage, and electronics, rely on submerged flat sheet membrane modules for water purification. These modules provide a reliable and efficient solution to meet stringent water quality requirements.

c) Wastewater Treatment and Reuse: Submerged flat sheet membrane modules play a crucial role in treating wastewater and enabling its safe reuse. They effectively remove pollutants, including suspended solids and bacteria, from wastewater, allowing it to be recycled for various non-potable uses, such as irrigation or industrial processes.

5. Contribution to Sustainable Water Management:

The adoption of submerged flat sheet membrane modules in water purification aligns with the principles of sustainable water management. These modules contribute to water conservation by enabling the reuse of treated water, reducing the reliance on freshwater sources. Additionally, the advanced filtration capabilities of submerged flat sheet membrane modules reduce the need for chemical disinfection, minimizing the environmental impact and operational costs associated with chemical usage.

Conclusion:

Submerged flat sheet membrane modules have revolutionized water purification by offering superior filtration performance, enhanced water recovery, consistent operation, and a space-efficient design. Their applications in municipal water treatment, industrial water purification, and wastewater treatment and reuse have significantly contributed to achieving sustainable and high-quality water treatment. By adopting submerged flat sheet membrane modules, water treatment facilities can ensure the delivery of clean and safe drinking water, meet stringent water quality regulations, and contribute to sustainable water management practices. As technology continues to advance, submerged flat sheet membrane modules will continue to play a vital role in revolutionizing water purification and addressing the global challenge of providing access to clean water for all.

About Jiangsu Peier membrane

iangsu Peier membrane corp.,Ltd(Stock Code: 836744) was established in 2007 with a registered capital of 48 million Yuan, referred to as “Peier membrane industry”.

It is a high-tech enterprise focusing on the R&D, production, manufacturing and service of MBR flat sheet membrane products. Its Peier Product category as below:

- Flat Sheet Membrane Element

- Flat Sheet Membrane Element-Single Nozzle

- Flat Sheet Membrane Element-Double Nozzle

- Flat Sheet Membrane Element-3D Soft Support

- Flat Sheet Membrane Element-Renovated Membrane

- Flat Sheet Membrane Module

- Flat Sheet Membrane Module-Module-Single Nozzle

- Flat Sheet Membrane Module-Module-Double Nozzle

- Flat Sheet Membrane Module-2S(Double Deck)

- Flat Sheet Membrane Module-3S(High Flux)

- Flat Sheet Membrane Module-Mini Module

- MBR System

- MBR System-Laboratory Test Equipment

- MBR System-Pilot Equipment

- MBR System-Package System

Peier membrane always adheres to R&D and cooperation with well-known universities at home and abroad, such as Tsinghua University, Sydney University, Nanjing University of technology, Changzhou University and Jiangnan University.

It is the editor in chief of the national industry standard HY/T252-2018 “submerged flat membrane element for water treatment”.

At present, it has 7 invention patents, 56 new utility patents, 4 software works and 1 appearance patent.