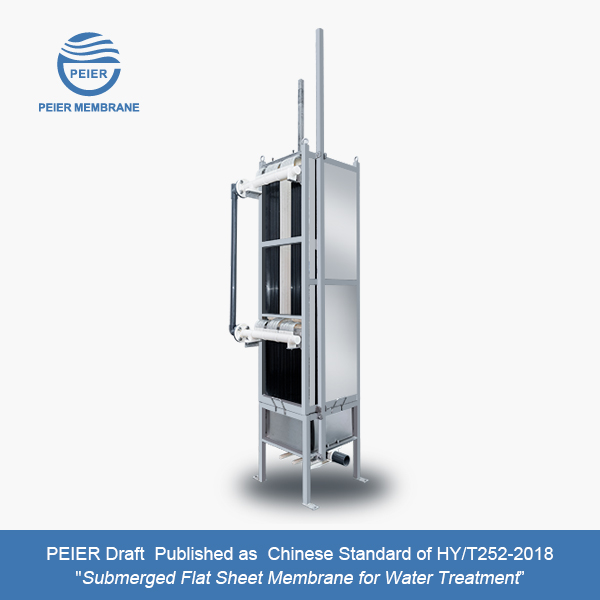

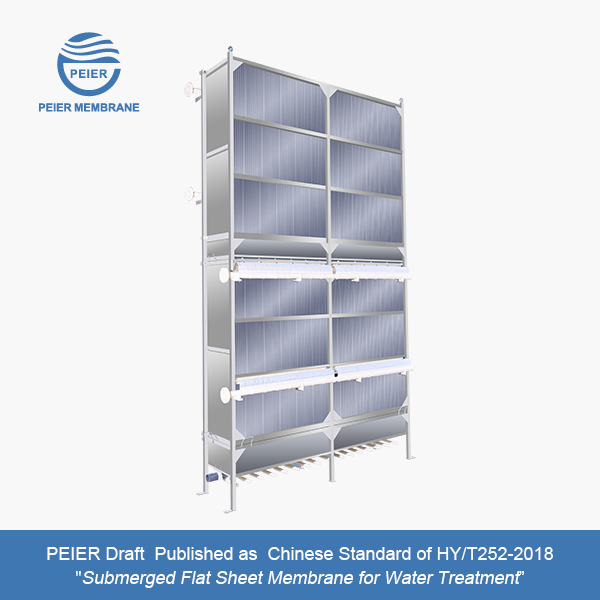

Flat Sheet Membrane Module-Module-Single Nozzle-Module-Single Nozzle

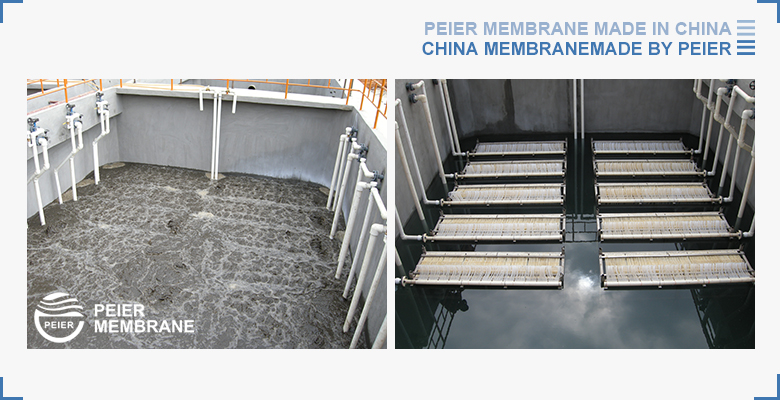

Peier MBR flat membrane has been widely used in industrial wastewater treatment and reclaimed water reuse projects at home and abroad, including medicine, mining, electronics, chemical industry, washing, large-scale municipal wastewater reuse projects.

Description

MBR Module-Single Nozzle

Ⅰ. Membrane box:

Main function:

To collect the filtered water from MBR system

● Flatsheet membrane component:core product to filter waste water.

● Water outlet hose:to connect water outlet spout Box of each membrane with water collection pipe.

● Water collection pipe:to collect filtered water.

Ⅱ.Aeration Box

Main function:

- To keep scouring for anti-pollution and provide oxygen for the microorganism in MBR tank.

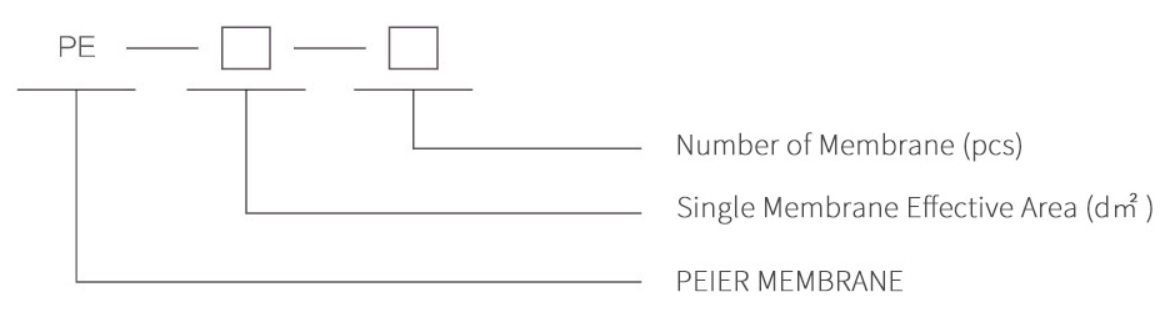

- Type of submerged membrane module is formed by English letter and Arabic numbers:

Membrane Module Naming

Type of submerged membrane module is formed by English letter and Arabic numbers:

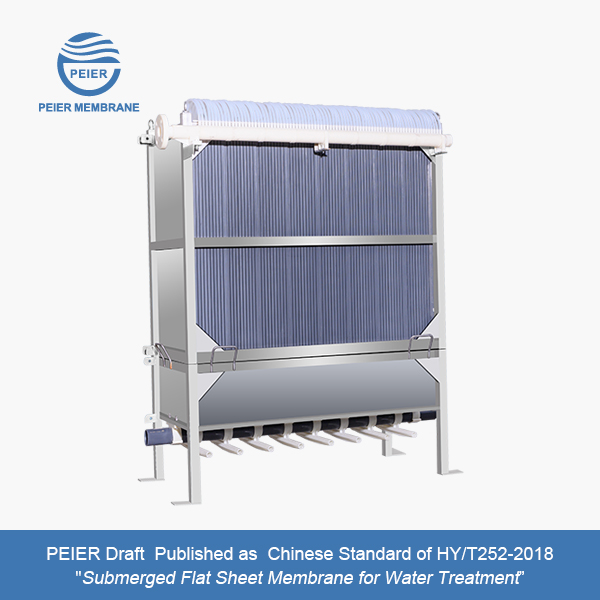

Model of Membrane Module

PEIER® Flat sheet membrane module.have two type of module which is signal nozzle and double nozzle,see table. According to the membrane surface aeration 08㎡,1.0㎡,1.5㎡.

MBR Module Table:

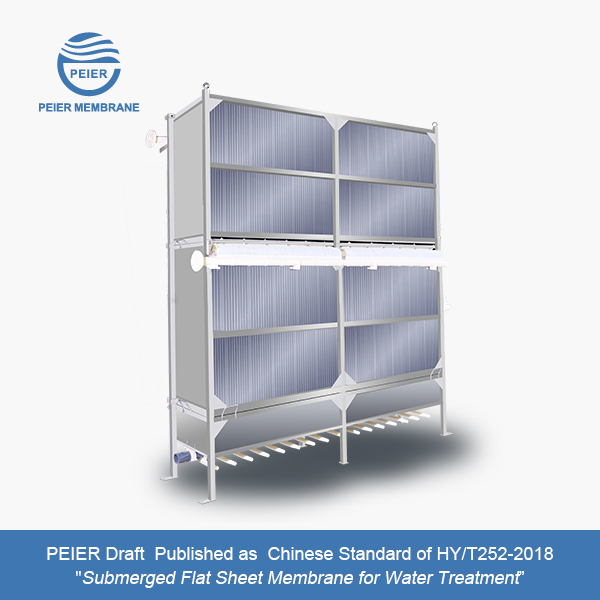

| Module | PEIER80-100 | PEIER100-100 | PEIER100-150 | PE150II-100 |

|---|---|---|---|---|

| Effective area (m)2/ (ft²) | 80 | 100 | 150 | 150 |

| Size (m)/(ft) (L*W*T) | 1.7x0.7x1.6 | 1.7x0.7x1.8 | 1.7x0.7x2.4 | 1.7x0.8x2.4 |

| Number of Membranes(pcs) | 100 | 100 | 100 | 100 |

| Output Capacity (m³/d) | 32~48 | 40~60 | 60~90 | 69~103.5 |

| Weight (kg)/ (lbs.) | 420 | 480 | 710 | 710 |

| Structure Material | SUS304/SUS316 | |||

| Aeration Material ABS | ABS(Acrylonitrile Butadiene Styrene) | |||

| Collection Pipe Material ABS | ABS(Acrylonitrile Butadiene Styrene) | |||

Remark:

1. Desien Flux parameters in the table was tested in the treatment of urban domestic wastewater at 25C and operation pressure-10kPa with a single panel of membrane.Tested method is execution the standard of HYT252-2018submerged flat membrane element for water treatment in China.

2. Wastewater from different sources may be distinguishing greatly,Adequate tests are necessary for different

users.Usually,domestic waste water design between 400-500 L//day,industry wastewater please contact with oun engineer.

3. PEIERmembrane module can be design from 20 pcs to 200 pcs in one module.PEIER* also have 0.1m or 025mpilot testing use,please contact us for further details.

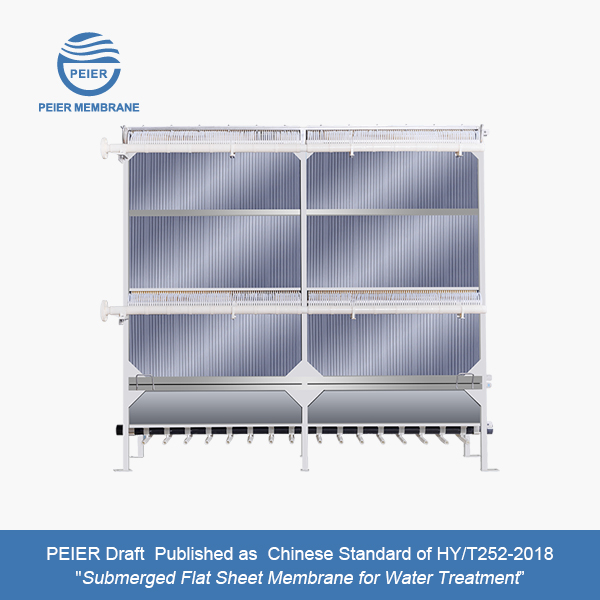

Membrane module series dimensions

NOTICE

- The suction pipe diameter of200 film modules is ND50.

- The suction pipe diameter ofless than200film modules is nd40.

- The overall height of the integrated membrane module is consistent with that of the split type.

Size unit: mm

| Module | Number of Membrane (pcs) | PEIER80 | PEIER100 | PEIER150 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | E | D | H | G | E | D | H | G | E | D | H | G | F | C | ||

| PEIERXX-20 | 20 | 386 | 606 | 774 | 584 | 1720 | 1630 | 802 | 611 | 1880 | 1790 | 774 | 584 | 2470 | 2380 | 600 | 248 |

| PEIERXX-30 | 30 | 534 | 754 | ||||||||||||||

| PEIERXX-40 | 40 | 682 | 902 | ||||||||||||||

| PEIERXX-50 | 50 | 830 | 1050 | ||||||||||||||

| PEIERXX-60 | 60 | 978 | 1198 | ||||||||||||||

| PEIERXX-70 | 70 | 1126 | 1346 | ||||||||||||||

| PEIERXX-80 | 80 | 1274 | 1494 | ||||||||||||||

| PEIERXX-90 | 90 | 1422 | 1642 | ||||||||||||||

| PEIERXX-100 | 100 | 1570 | 1790 | ||||||||||||||

| PEIERXX-110 | 110 | 1748 | 1968 | ||||||||||||||

| PEIERXX-120 | 120 | 1896 | 2116 | ||||||||||||||

| PEIERXX-130 | 130 | 2044 | 2264 | ||||||||||||||

| PEIERXX-140 | 140 | 2192 | 2412 | ||||||||||||||

| PEIERXX-150 | 150 | 2360 | 2580 | ||||||||||||||

| PEIERXX-160 | 160 | 2508 | 2728 | ||||||||||||||

| PEIERXX-170 | 170 | 2656 | 2876 | ||||||||||||||

| PEIERXX-180 | 180 | 2804 | 3024 | ||||||||||||||

| PEIERXX-190 | 190 | 2952 | 3172 | ||||||||||||||

| PEIERXX-200 | 200 | 3150 | 3370 | ||||||||||||||

Recommended Products

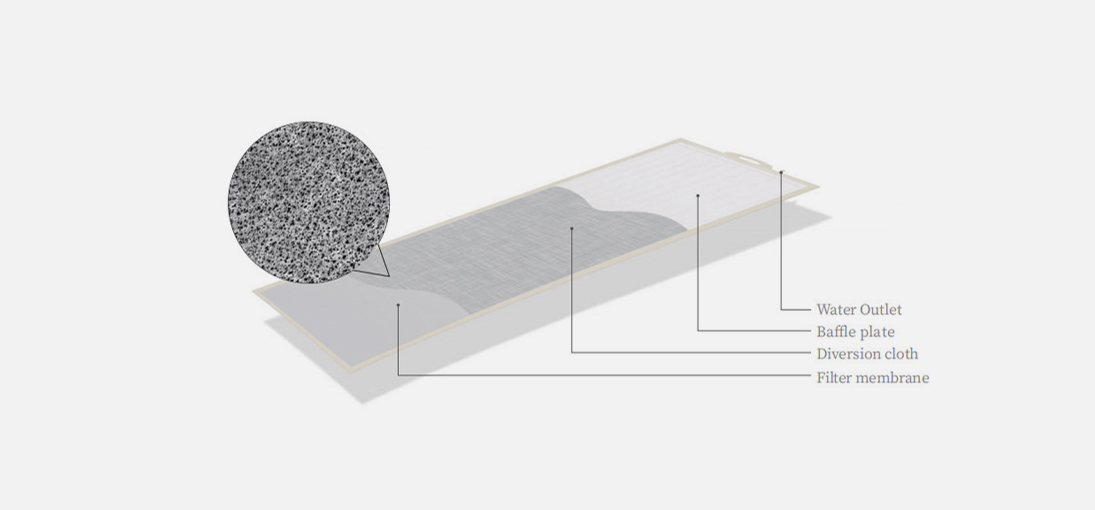

Membrane Element Composition

- Water Outlet

- Bffle Plate

- Diversion Cloth

- Filter Membrane

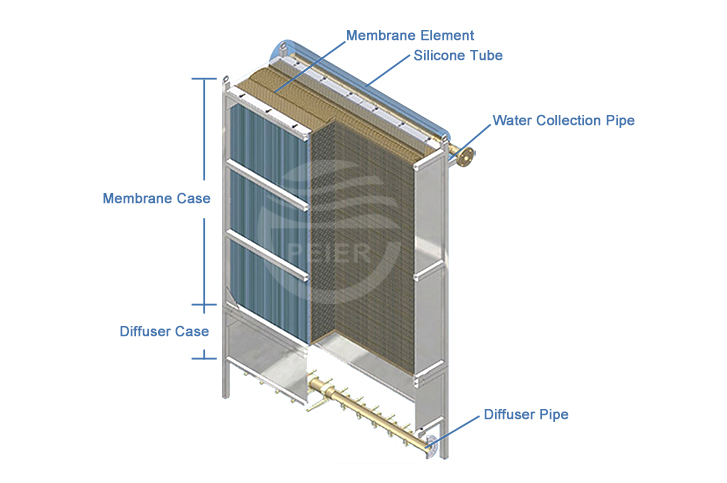

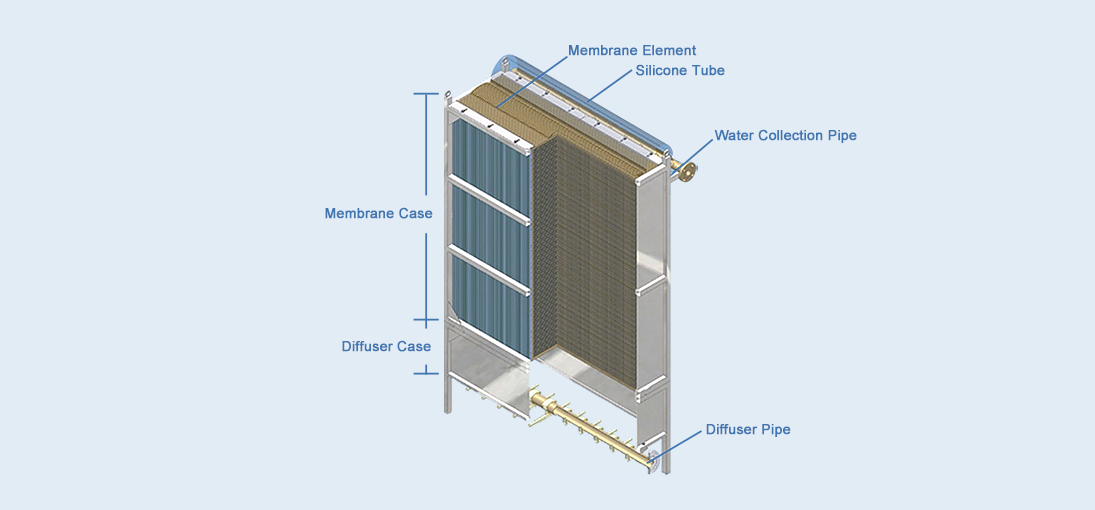

Membrane Modules And Their Components

- Membrane Cartridge

- Silicone Tube

- Water Collection Pipe

- Membrane Case

- Diffuser Case

- Diffuser Pipe

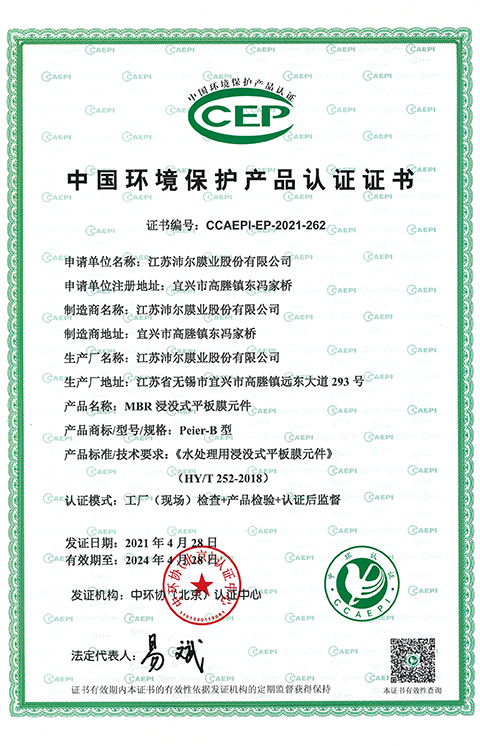

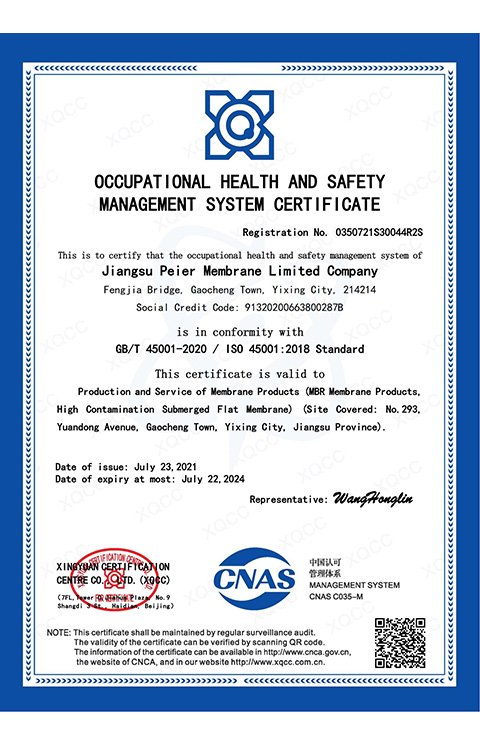

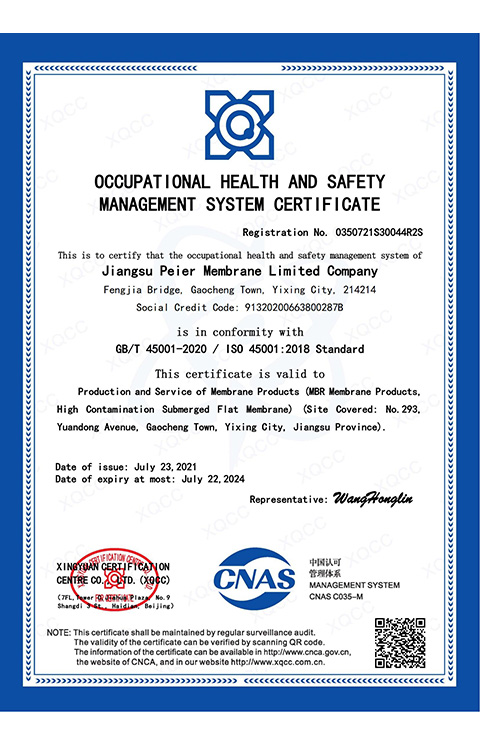

Our Cetificate

“Make good products, sell good products and let customers make good use of products” is the business purpose of the company.

> Intellectual property management system certificate R&D, production and sales of MBR flat membrane elements and MBR flat membrane components.

> CEP Cetificate of China

> ISO 9001 System Certificate Quality management system certificate

> ISO 9001 System Certificate Occupational health and safety management system certificate

> ISO 9001 System Certificate Environmental management system certificate

How We Work

“Make good products, sell good products and let customers make good use of products” is the business purpose of the company.

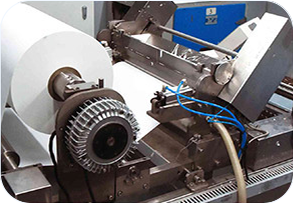

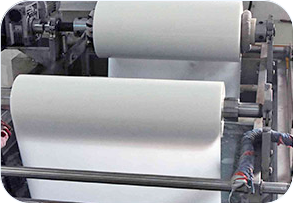

1. Blending →

2. Scraping →

3. Cleaning →

4. Cutting →

5. Oiling/Drying →

6.Membrane Assembly →

7. Stock Packing →

8. Module Assembly →

Case Study

“Make good products, sell good products and let customers make good use of products” is the business purpose of the company.

Dos Santos International Airport (Angloa) 500 m3 /d

Kunming Institute of Metallurgy Waste Water Project

5000 m3 /d

Service Support

“Make good products, sell good products and let customers make good use of products” is the business purpose of the company.

Contact With Us

What they’re talking about our service