In recent years, driven by the policy, the development of MBR flat film in China can be said to be equipped with an engine and wings, and it is rapidly rising! More and more environmental protection practitioners and environmental protection companies have begun to learn and carry out MBR process product manufacturing, process design and operation and maintenance management related businesses. But to put it bluntly, this is not something you can do if you want. Can you do it? how? It still depends on whether you understand MBR flat film or not.

01 MBR Flat Membrane Basics

With the great upsurge of the environmental protection industry in recent years, there are countless supporting environmental protection products. As a high-quality and efficient product, MBR flat membrane plays an important role in various sewage treatment projects.

1. Membrane element

The membrane element is mainly composed of four parts: diaphragm, lining cloth, support plate and water intake. The treated water filtered by the membrane flows through the support plate and is discharged from the water intake.

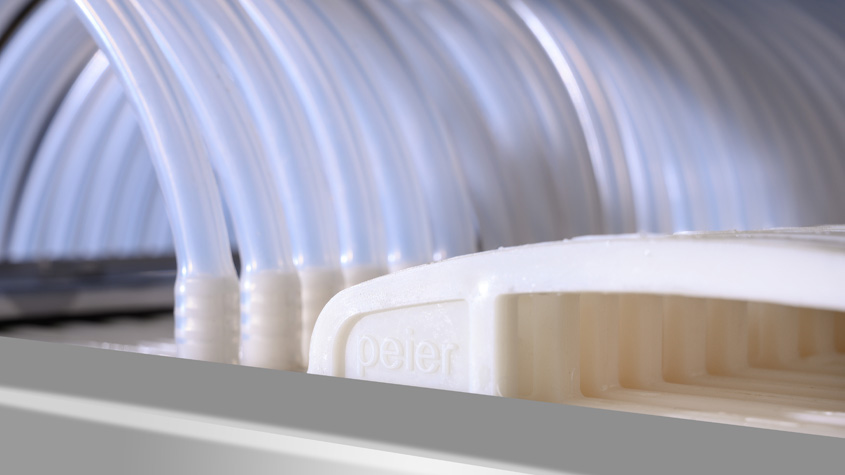

2. Membrane module

The membrane module single-channel double-stacked flat membrane module is composed of the upper membrane support and the lower aeration box. The membrane holder contains a certain number of membrane elements, and each membrane element is connected to the water collecting pipe through a transparent silicone tube. The aeration box contains aeration pipes for aeration and scouring to prevent the contamination of the flat membrane and to supply oxygen to the microorganisms.

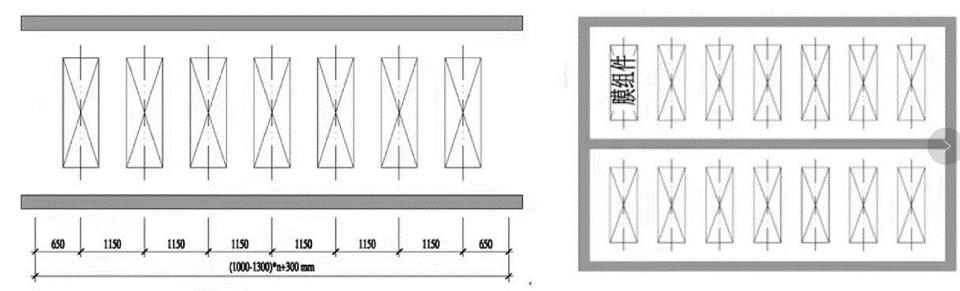

3. MBR membrane module arrangement

4. MBR flat film pretreatment requirements

The influent water of the MBR process needs to be pretreated to a certain extent, and the membrane bioreactor should meet the following conditions:

➤Chemical oxygen demand (COD)≤500mg/L;

➤Five-day biochemical oxygen demand (BOD5)≤300 mg/L;

➤Suspended solids (SS)≤150mg/L;

➤ Ammonia nitrogen (NH3-N)≤50mg/L;

➤Animal and vegetable oil (n-Hex) ≤10 mg/L, pH value 6~9;

➤Mineral oil (n-Hex) ≤3mg/L;

➤Calcium and magnesium ions (Ca2+, Mg2+) ≤ 100mg/L;

02 MBR flat film daily operation and maintenance

In the daily operation and maintenance management of MBR flat film, the following specific work items are required:

“Front” – observe the operation of the inlet pump to prevent the failure of the liquid level gauge from causing the inlet pump to rise above the water surface for emptying; check whether the grid is blocked.

“Medium” – observe the liquid level of the membrane tank to prevent the membrane module from exposing the water surface or the sewage overflowing the tank due to the failure of the liquid level gauge, and pay attention to the properties of the sludge. Observe and record whether the aeration of the membrane tank is uniform, and open the aeration vent valve for 5-10 minutes every week.

“After” – observe and record the operation of all electromechanical equipment, whether there is any different noise than usual. Observe and record the reading of the negative pressure gauge. When the transmembrane pressure difference reaches 35KPa, the membrane needs to be washed. Observe and record the flow meter reading, and adjust the outlet valve of the self-priming pump so that the flow is within the design flow. Observe whether the control panel is abnormal and whether the liquid level gauge works normally.

“Tail” – observe and record the water output, it should be clear and transparent without suspended matter.

“Edge” – pay attention to the surrounding environment, do not let sharp and hard objects enter the membrane pool.

03 MBR Flat Film FAQ

During the actual operation of the MBR flat film, failure is inevitable, but the important thing is to not panic to find out the cause of the problem, and solve the problem in a targeted manner.

1. What causes the turbidity of the effluent?

a. Underwater pipeline valve leakage;

b. The water collecting main pipe of the membrane module is damaged;

c. The silicone hose is loose or damaged;

d. The water outlet head is broken;

e. Diaphragm damage;

2. How to solve the turbidity of the effluent?

To lower the liquid level, add clean water from the dosing port to check for leaks. The diaphragm is checked using a small self-priming pump.

3. Why should the film washing and dosing time be controlled at about 15 minutes?

The purpose of fast dosing is to ensure that each membrane is filled with liquid medicine as much as possible, and a large amount of liquid medicine will not penetrate into the membrane surface and be wasted.

4. If the diaphragm needs to be taken out for inspection on site, and it will take a long time to be placed outside, how should the diaphragm be kept after taking it out?

Place it in a dark place and keep it moisturized with water every few hours, preferably soaked in clean water.

5. Is it possible to filter sewage directly with membranes without sludge culture?

cannot! If the membrane is directly used to separate the pollutants, the fouling of the membrane will occur quickly, and the separated pollutants will be enriched to a certain extent, so that the membrane cannot continue to be separated.

Regarding the common problems of MBR flat film, there are many researches and case practices of Jiangsu Peier Film Industry. A high-tech enterprise focusing on the research and development, production, manufacturing and service of MBR flat film products. Peier Membrane has always adhered to the research and development and cooperation with well-known universities at home and abroad such as Tsinghua University, Sydney University, Nanjing University of Technology, Changzhou University, Jiangnan University, etc. “The editor-in-chief of the standard, currently has 6 invention patents, 37 new utility patents, 4 software works, and 1 appearance patent.

Abuot Jiangsu Peier membrane

Jiangsu Peier membrane corp.,Ltd(Stock Code: 836744) was established in 2007 with a registered capital of 48 million Yuan, referred to as “Peier membrane industry”.

It is a high-tech enterprise focusing on the R&D, production, manufacturing and service of MBR flat sheet membrane products. Its Peier Product category as below:

- Flat Sheet Membrane Element

- Flat Sheet Membrane Element-Single Nozzle

- Flat Sheet Membrane Element-Double Nozzle

- Flat Sheet Membrane Element-3D Soft Support

- Flat Sheet Membrane Element-Renovated Membrane

- Flat Sheet Membrane Module

- Flat Sheet Membrane Module-Module-Single Nozzle

- Flat Sheet Membrane Module-Module-Double Nozzle

- Flat Sheet Membrane Module-2S(Double Deck)

- Flat Sheet Membrane Module-3S(High Flux)

- Flat Sheet Membrane Module-Mini Module

- MBR System

- MBR System-Laboratory Test Equipment

- MBR System-Pilot Equipment

- MBR System-Package System

Peier membrane always adheres to R&D and cooperation with well-known universities at home and abroad, such as Tsinghua University, Sydney University, Nanjing University of technology, Changzhou University and Jiangnan University.

It is the editor in chief of the national industry standard HY/T252-2018 “submerged flat membrane element for water treatment”.

At present, it has 6 invention patents, 46 new utility patents, 1 appearance patent and 4 software works.